So I have a front triangle and some chains stays with dropout already on. So it’s time to put the two sub assembly’s together. You can just use a dummy axle and for tig welding that’s normally fine but with a lug with a lot of heat in its going to move around a bit. So i prefer a old wheel that straight a some plates clamped down. this means you can hold it straight in all plains why you braze.

Next i need to file the offset miters of the seat stays these are over sized 17mm Columbus spirit ones to match the rest of the frame. I had adjusted the dimension in the frame design tool (rattle cad) and it gives you a nice PDF of the miter profile you can print and use a template.

Then using a old tig rod to hold the stays in place you can braze them to the seat tube so they are tidy around the clamp and top tube. Looks messy due to the flux but shoudl be nice on clean up.

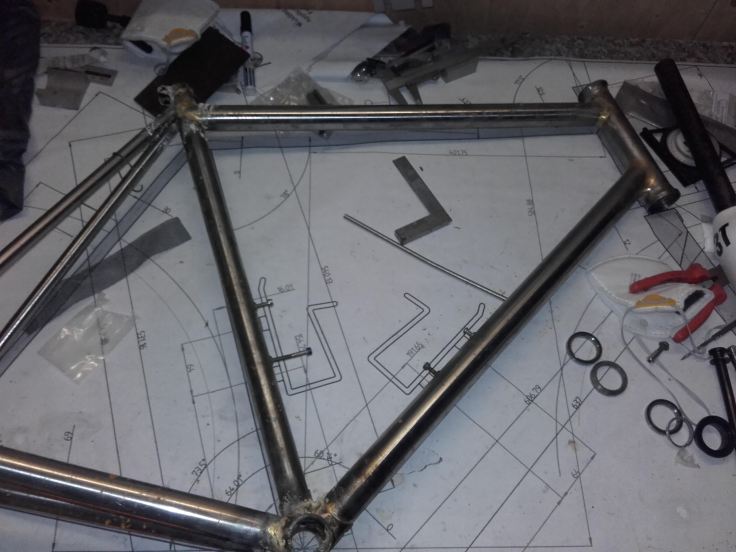

Back to the drawing to make sure we are still in shape.

Next time brazons, clean up and paint time.

Leave a comment