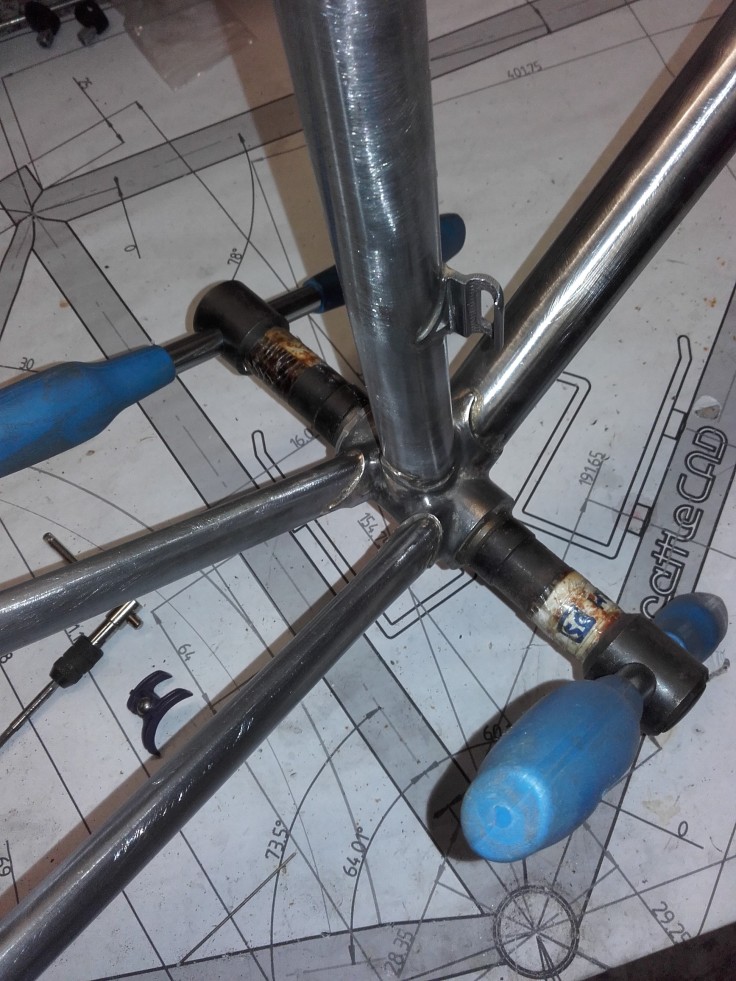

Right next is the braze-on’s, 55% or 45% sliver for most of the work, its works at low temperature and flows nicely. I am using the lovely Llewellyn limpet braze-on’s across the frame. You can use spokes or tig wire to hold them in place while you solder them in. Silver flux come off easy with a hot water and a brush. then i drill the seat clamp and cut out the slot and file. Next is clean up.

Next is to real the seat post, i use a fixed 27.2 ream and then chase it out with an adjustable ream until the post glides in and out

Need to ream the bottle mounts

Need to ream the bottom bracket and face it.

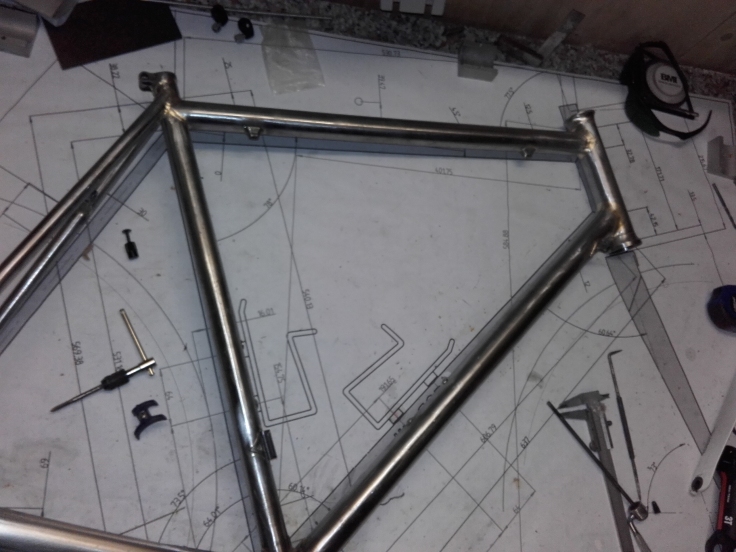

Need to check the alignment, a quick tweak and we are good.

Final check against the drawing. it straight down the center line.Top tube is to 1mm, head tube is spot on, seat tube is to 1mm, bb is spot on , drop out height against the bb (bb drop) is 3-4 mm higher than i wanted. mmm not sure why i did not spot that. But a quick estimate shows that the simple take the head angle from 73 to 72.75 degree. which i can live with. but from a jig-less build that not bad.

Next time is fine finishing and primer paint.

February 24, 2016 at 10:55 am

Looking very good Mr Levy

I think you’ve missed your vocation

February 24, 2016 at 12:45 pm

Thanks but it dont pay the bills yet!!