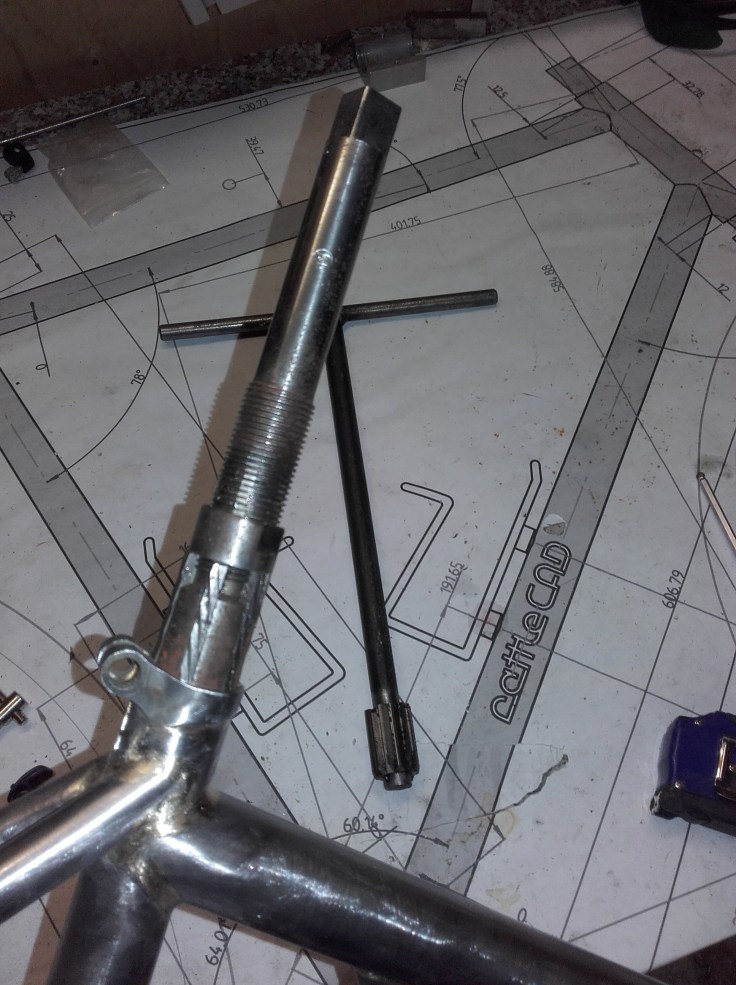

So in the new plan I am going with a oversize lightweight bottom bracket lug. So I have assembled and done some checks. With a very minor tweak to the lug it fits perfect. So since i don’t have a jig i am going to braze the lug one joint at a time, which is a paint for clean up (have to do it each time) but means you can make sure of alignment without a jig or pins.

So next I ported and cleaned up all the slots for the tubes. they need to be shiny and clean and big enough of the braze to move through. I will tack the seat tube in the bottom bracket lug, check its straight then braze it in.

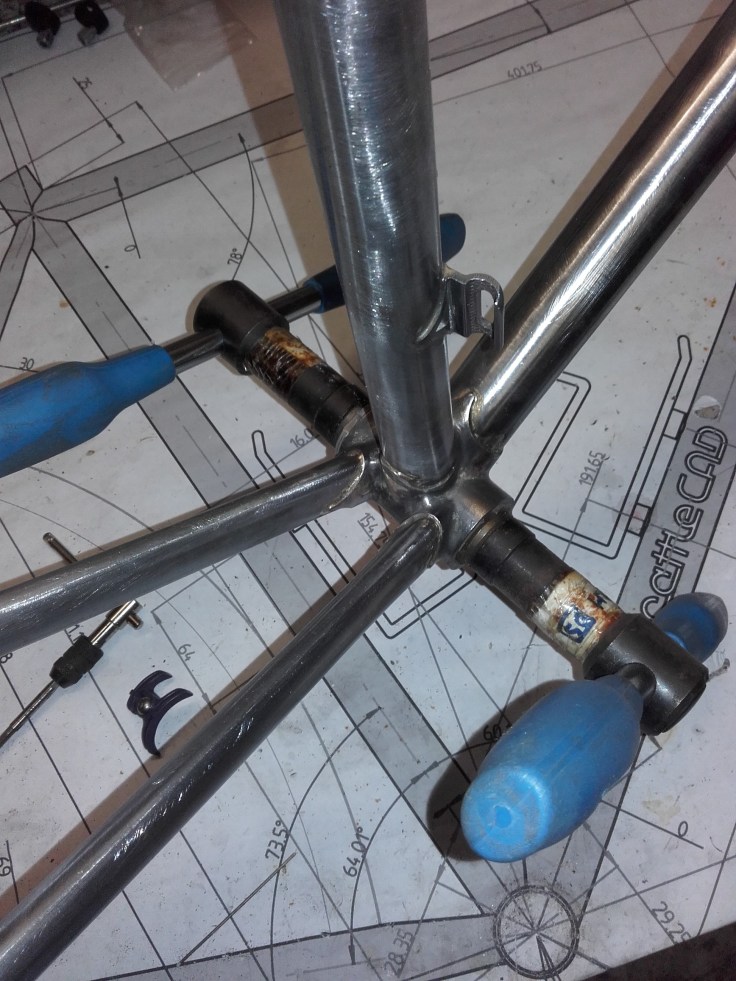

I need to the get the braze all the way through the lug. So we need more heat that mean changing the number on tip of the torch to a no 5 or 6 and setting the flame to a roaring (but not hissing flame)You can see that in the colour if you get the whole area cheery red then add the rod you can see the colour change as the braze moves through the joint following the heat. you need to get it through to the inside. after you need to check the inside of the joints. Because I am using a lot of heat i need to check the braze alloy has not split.

you can see this is the copper colour is in the braze. There is some splitting on the outside of the lug but that fine. all good.

Then check its all straight. clamp the BB and measure the gap against the flat surface. it should be the same on both sides. I am 0.2mm out but that is better than I normally get so I am happy.

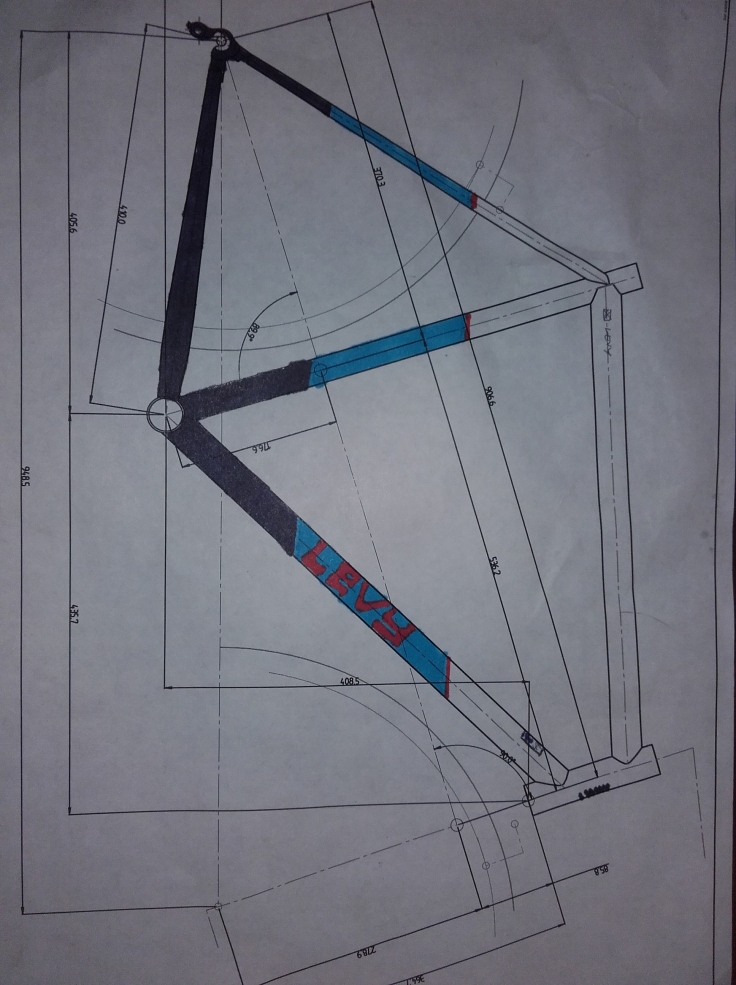

Next I align the front heat tube assembly with the seat tube and make sure its flat and the right angle and measure the seat tube the head tube. i then weight it and slide it off the table to braze it. this keeps it straight in the vertical plane of the frame and the head tube to seat tube measurement make sure we maintain the distance and angles. This method works for lugs and fillet and TIG welding.

Tack it, check its braze it, check it. done.

I did the bottle bosses at the same time using 55% Silver as the tube is thin in the middle. Next time top tube and chain stays.